Manufacturing

BERODE Engineering GmbH

Design, production and service from a single source

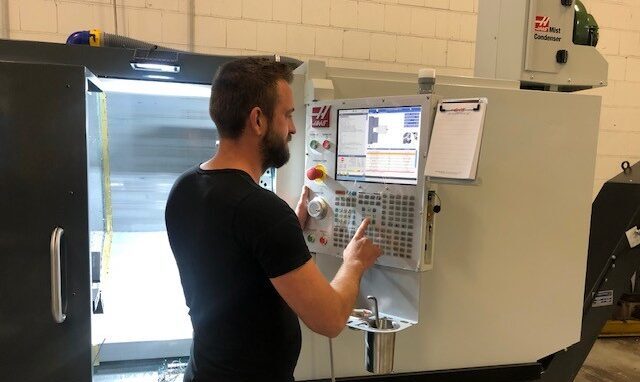

BERODE has decided to maintain its own production facilities so that our value engineering team can implement the identified and designed product concepts for our customers more quickly and efficiently. After the takeover in spring 2022, we transformed the production facility in Mechernich near Cologne, which was initially established as a repair store for local large companies, into a modern production facility for individual parts and small series. An ideal prerequisite for the fast and precise production and assembly of prototypes. This step was made possible by the introduction of modern CNC turning and milling technology in combination with existing production technology such as water jet cutting, sheet metal edging, welding and assembly expertise.

In addition, we use the know-how gained in this way to support our product cost analyses and carry out disassembly studies. This also enables us to map best practice manufacturing processes and transfer this knowledge to our customers.

For our customers, we are the partner who accompanies a project from the initial conceptual idea of a cost-efficient product solution through to a ready-to-install component.

Whether individual parts or complex assemblies, prototypes or series, we offer comprehensive solutions for all aspects of CNC technology. Using state-of-the-art processes and many years of experience, we manufacture precise components by turning, milling and water jet cutting. In addition to the pure production of parts, we can also assemble entire assemblies on request and organize purchasing and supplier management. If required, we provide support right from the design stage and accompany projects from the initial idea to the finished product.

Rely on quality, efficiency and a production team that thinks along with you. We look forward to your inquiry!

Our services:

- Production of turned and milled parts

- Cutting of various materials using water jet technology

- Creating welded constructions from structural steel, aluminum, stainless steels

- Production and approval of prototypes and small series

- Fixture and gauge construction

- Analyses in the materials laboratory (X-ray fluorescence analyses, coating thickness, hardness and roughness testing)

- Quality management: preparation of initial sample test reports, cooperation with the BAAINBw quality inspection body

Our manufacturing processes:

Water jet cutting

Omax 55100 Jet Machining – 3-axis CNC waterjet cutting system

- Max. Production X: 2,500 mm

- Max. Production Y: 1,340 mm

- Max. Production Z: 160 mm

Turning

Haas ST30Y – CNC turning center

- Driven tools

- Machining diameter: max. 381 mm

- Machining length: max. 826 mm

Conventional turning

- Machining diameter: max. 300 mm

- Machining length: max. 1500 mm

Milling

Hurco VM2 – 3-axis CNC machining center

- Max. Production X: 1,016 mm

- Max. Production Y: 457 mm

- Max. Production Z: 460 mm

Conventional milling

- Max. Production X: 650 mm

- Max. Production Y: 370 mm

- Max. Production Z: 370 mm

Further services

In addition to manufacturing, we also take on the production of welded assemblies or the assembly of individual parts into complete assemblies – precisely, reliably and on time. You benefit from our holistic approach: we not only coordinate internal processes, but also take care of the procurement of required components and standard parts via our network of suppliers in Germany and abroad.

Thanks to our many years of experience in supplier management, we know what is important: quality, availability and costs must be right with maximum transparency for our customers. We take care of ordering, communication and deadline monitoring so that you can rely on a ready-to-install result.

Design & planning

In addition to production, we also support you in the design and planning of your components. Whether CAD modeling, technical design or drawing derivation – we bring your ideas efficiently and precisely on the way to production. With modern machinery, many years of experience and high quality standards, we realize tailor-made solutions for a wide range of industries.